Generative design and 3D printing are at the forefront of a revolution in the design and manufacturing industries. By harnessing the power of advanced algorithms and additive manufacturing techniques, these technologies are enabling designers and engineers to push the boundaries of what’s possible. This article delves into the transformative impact of generative design and 3D printing, exploring their applications, benefits, and the future they are shaping.

Table of Contents

- 1 What is Generative Design?

- 2 The Evolution of 3D Printing

- 3 How Generative Design and 3D Printing Complement Each Other

- 4 Applications Across Industries

- 5 The Process of Generative Design and 3D Printing

- 6 Challenges and Considerations

- 7 Future Trends and Innovations

- 8 KEEP LEARNING

- 8.1 Best 3D Printing Software (Modeling and Slicing) for Beginners: 10 Free Options

- 8.2 The Ultimate Guide to the Best 3D Printing Software for Beginners

- 8.3 The Ultimate Beginner’s Guide to 3D Printing: Get Started Today

- 8.4 3D Printing and How Does It Work? A Comprehensive Overview

- 8.5 The Ethical Implications of 3D Printing: Navigating Legal and Regulatory Challenges in the Digital Age

What is Generative Design?

Generative design is an iterative design process that uses algorithms to generate a wide range of design solutions based on specific parameters and constraints. It leverages the power of artificial intelligence and machine learning to explore all possible configurations, often resulting in innovative and highly optimized designs.

Key Features of Generative Design

- Automated Optimization: Uses algorithms to optimize designs for specific criteria such as weight, strength, and cost.

- Innovative Solutions: Generates novel solutions that may not be intuitive to human designers.

- Rapid Prototyping: Allows for quick iteration and refinement of design concepts.

The Evolution of 3D Printing

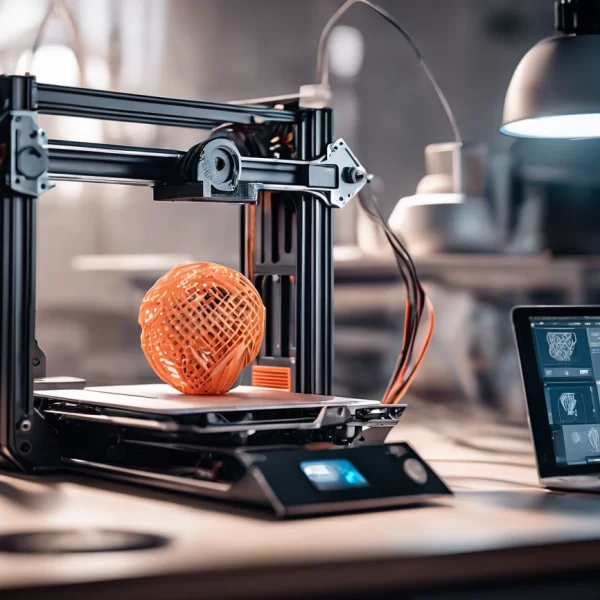

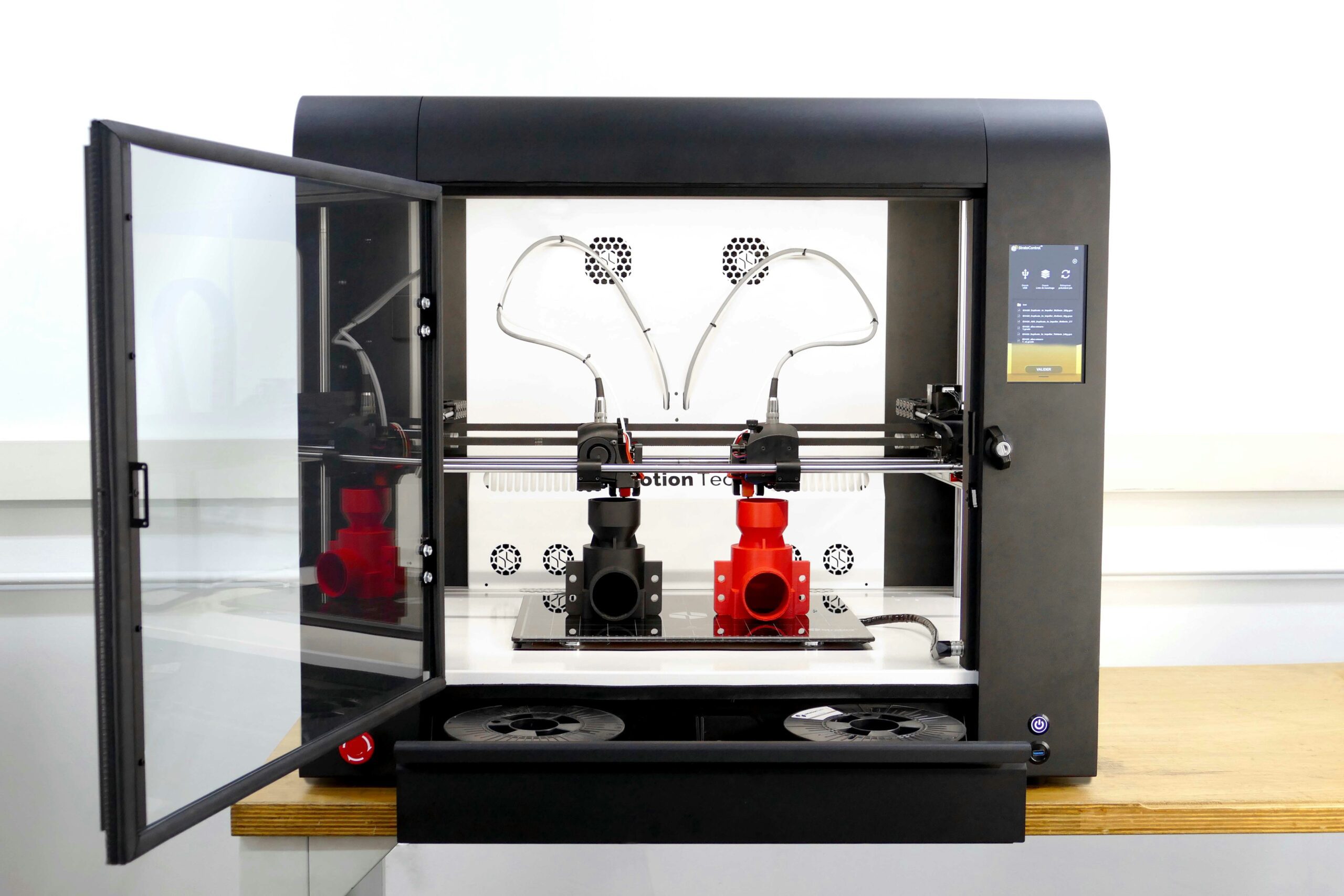

3D printing, also known as additive manufacturing, has evolved significantly since its inception. From simple prototypes to complex, functional parts, 3D printing now spans various industries including healthcare, aerospace, automotive, and consumer goods.

Types of 3D Printing Technologies

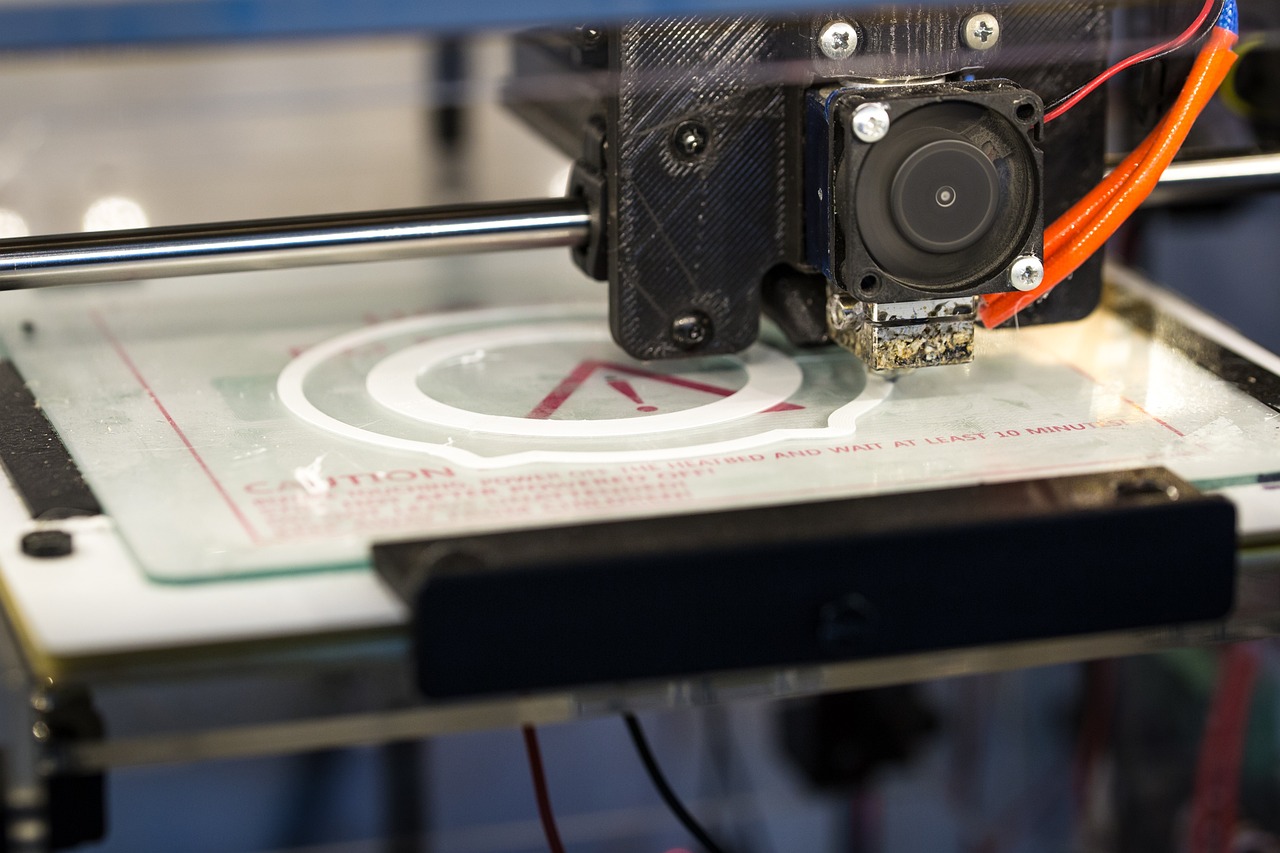

- Fused Deposition Modeling (FDM): Ideal for prototyping and small-scale production.

- Stereolithography (SLA): Known for high-resolution and smooth surface finishes.

- Selective Laser Sintering (SLS): Suitable for producing durable, functional parts.

- Digital Light Processing (DLP): Used for high-speed and high-resolution printing.

How Generative Design and 3D Printing Complement Each Other

Generative design and 3D printing are a perfect match, with each technology enhancing the capabilities of the other. Generative design creates complex, optimized geometries that are often impossible to produce using traditional manufacturing methods. 3D printing, with its ability to create intricate designs layer by layer, brings these innovative concepts to life.

Advantages of Combining Generative Design and 3D Printing

- Complex Geometries: Easily produce complex and customized designs.

- Material Efficiency: Minimize material usage while maximizing strength and functionality.

- Speed and Flexibility: Rapidly iterate designs and make adjustments on the fly.

Applications Across Industries

The combination of generative design and 3D printing is transforming a wide range of industries. Here are some notable applications:

Aerospace

- Lightweight Structures: Optimize components for weight reduction while maintaining strength, leading to significant fuel savings.

- Thermal Management: Develop advanced cooling systems with optimized airflow and heat dissipation.

Healthcare

- Customized Implants: Create patient-specific implants and prosthetics that perfectly fit individual anatomies.

- Surgical Tools: Design and produce bespoke surgical instruments for specific procedures.

Automotive

- Performance Parts: Manufacture lightweight, high-performance parts that enhance vehicle efficiency and performance.

- Rapid Prototyping: Quickly iterate and test new designs, accelerating the development cycle.

Consumer Goods

- Personalized Products: Enable mass customization, allowing consumers to personalize products to their exact preferences.

- Sustainable Manufacturing: Reduce waste by using only the necessary material for each product.

The Process of Generative Design and 3D Printing

Understanding the process from concept to final product is crucial for harnessing the full potential of these technologies.

Step 1: Define Design Goals

Set specific objectives and constraints such as weight, strength, material, and cost.

Step 2: Generate Design Options

Use generative design software to explore a wide range of potential solutions.

Step 3: Evaluate and Refine

Analyze the generated designs and select the most promising options for further refinement.

Step 4: Prototype with 3D Printing

Produce prototypes using 3D printing to test and validate the designs.

Step 5: Final Production

Finalize the design and proceed with full-scale production using 3D printing.

Challenges and Considerations

While generative design and 3D printing offer immense potential, there are challenges and considerations to keep in mind.

Material Limitations

Not all materials are suitable for 3D printing, and the properties of printed materials can vary.

Design Complexity

The complexity of generative designs can sometimes pose challenges in terms of manufacturability and post-processing.

Cost

While costs are decreasing, high-quality 3D printing and generative design software can still be expensive.

Future Trends and Innovations

The future of generative design and 3D printing is bright, with ongoing advancements promising even greater capabilities.

AI and Machine Learning

Further integration of AI and machine learning will enhance the generative design process, making it even more intuitive and powerful.

Advanced Materials

Development of new materials with enhanced properties will expand the applications of 3D printing.

Hybrid Manufacturing

Combining traditional and additive manufacturing techniques will offer new possibilities for creating complex, high-performance parts.

Generative design and 3D printing are unlocking limitless design possibilities, transforming industries, and redefining the future of innovation and manufacturing. By leveraging these technologies, designers and engineers can create optimized, customized, and highly efficient solutions that were previously unimaginable. As advancements continue, the synergy between generative design and 3D printing will undoubtedly lead to even more groundbreaking innovations.